Automotive Industry

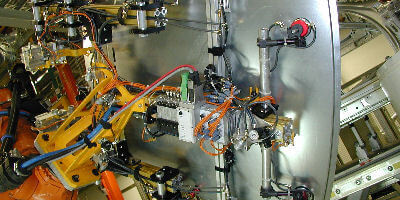

Magnetic handling in connection with robots support easy passage of steel parts in production line. It reduces production time and saves costs.

Growing productivity in the automotive industry requires savings on both time and money. To this end, magnetic principles are utilised for handling sheet metal and parts. This simplifies processes such as separation of stacked steel (even greasy) sheets, which are then accurately delivered one by one into the production machine.

Magnetic systems ferromagnetic components and sheet metal are successfully combined in handling with robots. They are also used for solid fastening of parts for further processing (grinding, polishing).

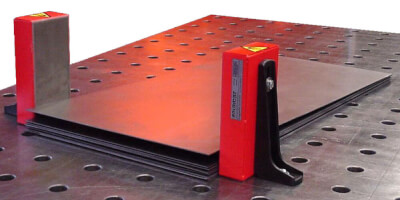

After magnetic handling does its work, the product may be left with undesirable residual magnetic effects. Even that, however, is not an obstacle for us, as our demagnetising tools will ensure that the part is ready for further processing or end use.

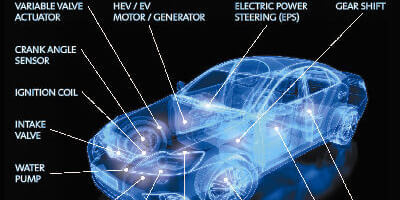

Magnets, or, more precisely, hard magnetic materials are hidden in many parts of a car. Not just in dozens of permanent-magnet electric motors, but in transmissions, sensors, brakes, engines, etc.

Want to read more? Take a look at the related documents.

Need help? Write us

Magnets Assist in Automating Car Production

|

|

Magnetic grippersRotate bodywork parts in the production line. |

Magnetic conveyorsTransport metal sheets for further processing. |

|

|

Demagnetising tablesRemove undesirable residual magnetism from steel parts.

|