Chemical Industry

Removal of ferromagnetic particles from raw materials and protection of technological equipment via magnetic systems with high resistance to chemicals.

Undesirable ferromagnetic particles that pollute the material for processing and subsequently affect the quality of the end product may enter the material during production even in the chemical industry. The solution is installing a magnetic system and detectors into the technological line in order to collect these particles from powdered, granulated and liquid materials. Due to the aggressive nature of the majority of chemicals and materials, it is vital to choose a suitable resistant material for building the magnetic and detection system.

It is also important for the industry that the system is completely self-cleaning. To this end, we provide various types of magnetic filters and cleanflow magnets for applications in the chemical industry, including for high-pressure processes.

Want to read more? Take a look at the related documents.

Need help? Write us

Related documents

Strong Magnets Monitor the Quality of End Products

|

Magnets with external poles filter ferromagnetic particles such as iron and steel in sizes from 50 μm to 50 mm from powdery and granulated materials transported in vertical pipelines. |

|

N Neodymium magnetic grids capture undesirable Fe particles sized 30 µm and above from freely flowing powdery or finely granulated materials, and are easy to clean via extraction pipes. Not even weakly magnetic particles will escape. |

|

|

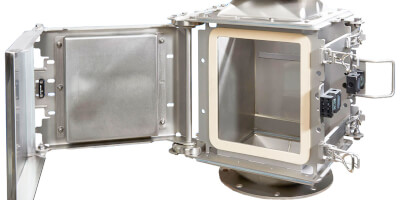

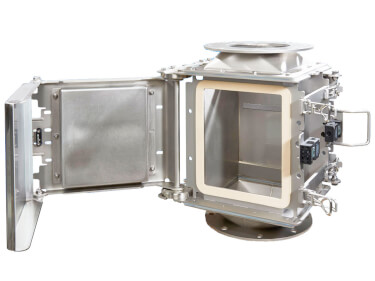

Cleanflow magnets with automatic cleaning without interrupting the flow of product, dust resistant, in ATEX II 1/2 D design. |