Food Industry

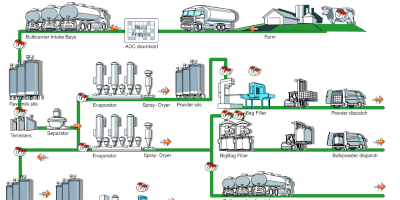

The main benefits of our solutions in food processing are prevention of contamination of the final product by metallic particles and protection of technological equipment.

Contamination of products by large or small metallic particles that may enter products such as baby food, fruit juices, powdered milk, spice, chocolate, flour, cereal, sugar, frozen vegetables and others during processing may cause a number of problems. Metallic particles pollute expensive products and endanger the health of the end user or irreversibly damage technological equipment and cause downtimes. These come with high costs as well as loss of good reputation of the company.

An efficient solution is the use of our highly sophisticated magnetic filters and separators, capable of capturing even stainless steel particles (AISI304, AISI316(L)). These machines undergo continuous innovation in partnership with quality management departments in the food industry in order to be able to guarantee safety and sanitary conditions of food in accordance with strict standards (EHEDG, HACCP, ISO).

Want to read more? Take a look at the related documents.

Need help? Write us

Related documents

Magnets Protect Both Production Equipment and People's Health

|

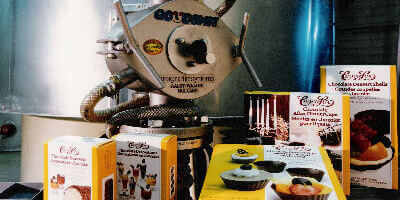

Prevention of Contamination of Final ProductDouble-walled magnetic filter uses hot water to ensure materials such as chocolate remain liquid to prevent them from coagulating on the magnetic rods. |

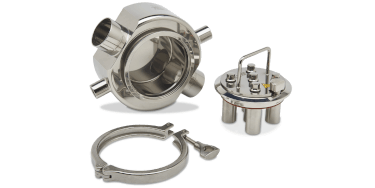

Hygienic DesignSpecial hygienic variants of magnetic filters are finely polished and surface-treated on the interior surface to prevent bacteria from gathering. Designs in accordance with EHEDG standards available. |

|

|

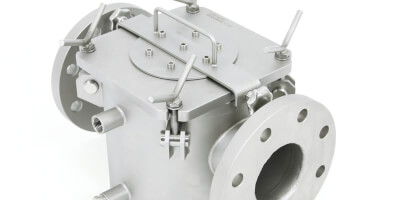

Protection of Technological EquipmentPipe magnet is a simple solution for protecting moulding machines, mixers, crushers and other equipment from damage caused by undesirable ferrous particles. Installed into pipe transport lines.

|