Pharmaceutical Industry

Removal of undesirable particles of stainless steels AISI 304, 316 and 316 L from materials for processing.

Materials processed in the pharmaceutical industry do not contain many undesirable ferrous particles that would contaminate the resulting product. However, they may contain particles of stainless steels AISI 304, 316 and 316L, which are non-magnetic and require the use of magnetic systems with extremely powerful magnets and appropriate design to detect and remove them. The industry also places high demand on the quality of surface treatment and the ability to easily and thoroughly clean the equipment due to the need to work in a clean environment.

For applications in the pharmaceutical industry, we utilise e.g. an EHEDG magnetic filter and EHEDG hydroform cleanflow magnets developed by our partner Goudsmit Magnetics.

Want to read more? Take a look at the related documents.

Need help? Write us

Increasing the Value of Products in Clean Environments

|

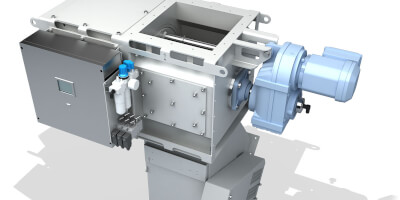

Cleanflow magnetic separators – separate undesirable ferromagnetic particles from flowing powdery mixtures and fine granulates with maximum particle size of up to 10 mm. |

|

Magnetic filters filter ferromagnetic pollutant particles as well as weakly magnetic particles such as stainless steel residues from liquids or powders that are being transported under pressure. |

|

|

EHEDG magnetic filter – Clean in Place – special hygienic variants of the magnetic filter are finely polished and surface-treated on the interior surface to prevent bacteria from gathering.

|