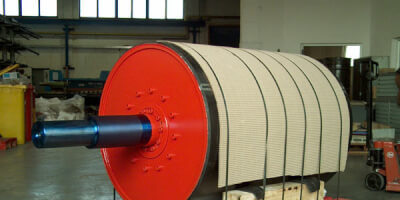

Permanent Magnetic Headrollers

Protection of technological equipment from damage, increased value of primary and secondary raw materials. For high occurrence of ferrous particles. Compact solution with simple installation.

Branches: recycling | processing of minerals | agriculture | chemical industry

Magnetic headrollers with permanent magnets are installed at the ends of a belt conveyor as drive roller. The separation of magnetic and non-magnetic material thus takes place at the very end of the conveyor. Magnets attract ferrous objects, while non-magnetic objects continue onward.

A great advantage of this solution is direct contact between the magnetic field and the product. Because of that, the rare-earth magnetic cylinders are capable of separating even weakly magnetic particles (stainless steel, paramagnetic materials). Magnetic cylinders are also installed in combination with overband magnetic separators as a second stage of iron removal in order to achieve a finer sorted product.

Ferrite headrollers we produce as standard with diameters D160, 200, 220, 250, 320, 400 mm. Neodymium headrollers with diameters D110, 130, 160, 200, 220, 250, 320, 400 mm. We also offer special headrollers with diameters D630, 800, 508 and 1200 mm. We ussually customize the production according to the customer's application.

Need help? Write us

Want to know more? Take a look into our international technical database to see detailed product specifications.

You will be redirected to the joint technical database of the Goudsmit Magnetics group for a detailed description of the product.

I agree to redirecting Cancel redirecting