Metalworking Industry

Magnetic handling, transport and fastening of parts. Demagnetising of products. Recycling of blasting agents. Magnetic filtration of liquids.

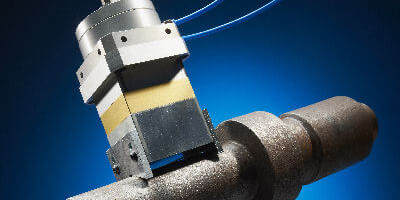

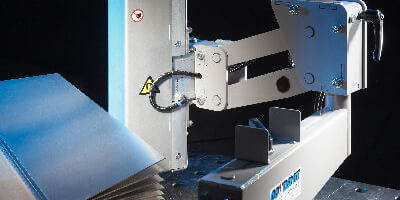

Magnets are an obvious choice for use in metalworking. They enable simple, quick and non-destructive fastening of components for machining and transport of parts for further processing in automated operation. Magnets offer interesting opportunities for efficient production processes. Demagnetising systems are a necessity when it comes to removing residual magnetism before surface treatment.

Magnetic filters capture even micron-sized and weakly magnetic impurities found in cutting and cleaning fluids or coating systems.

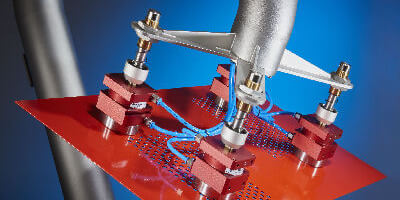

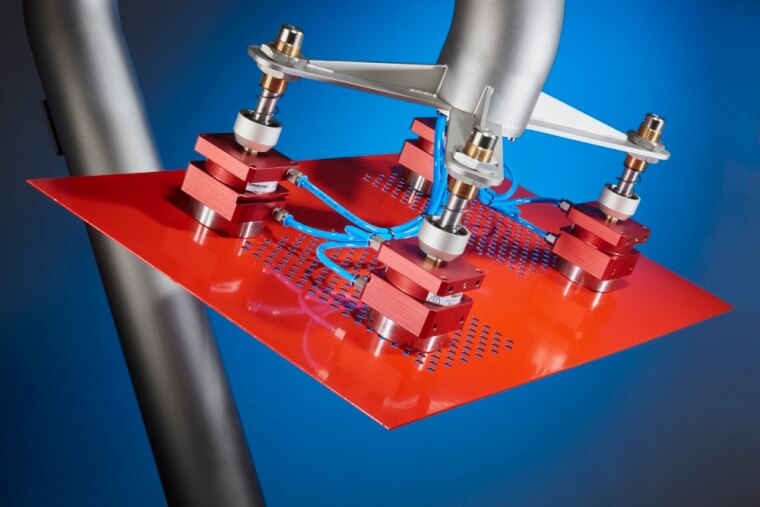

We have a number of magnetic systems for handling steel sheets, whether they are used for fixating components during laser welding or simple and quick fastening and transport of steel sheets during interoperational transport. An attractive choice is using a magnetic gripper to transport even perforated plates by employing a combination of magnets and vacuum.

Steel sheets are often greasy and they cling to one another when stacked up. Handling such a material becomes rather complicated. Magnetic sheet separators, however, are capable of safely separating them and transporting them one by one for further processing.

Need help? Write us

Related documents

Mezioperační doprava pomocí magnetů

|

Magnetické unašeče dokáží přesouvat také perforované plechy. |

|

Magnetické čeřiče plechů uvolní a oddělí lepkavé nebo mastné ocelové plechy. Brání také poškození nástrojů a chybnému odebírání více plechových dílů najednou v automatizovaných provozech. |

|

|

Břemenové permanentní magnety usnadňují upevnění a zvedání výrobků z oceli.

|