Drum Magnetic Separators

Protection of technological equipment, increased product value. For loose materials with high contamination by ferromagnetic materials in pipelines. Continuous cleaning.

Branches: agriculture | food | processing of minerals | recycling

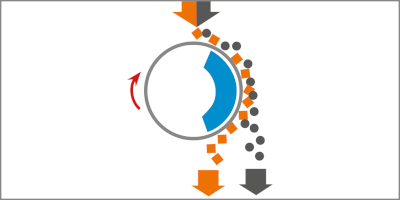

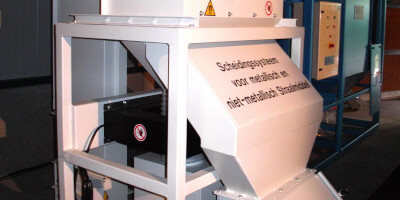

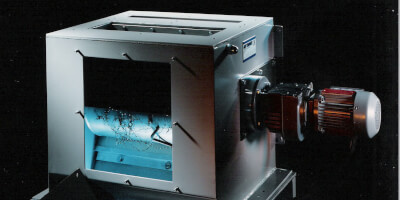

Drum separators remove undesirable ferrous particles or even weakly magnetic stainless particles loosened by abrasion that may enter the product stream during production. They are cleaned continuously, making them ideal for separating large amounts of Fe particles. The magnet thus remains clean, guaranteeing maximum magnetic force. This type of separators is used to cleaning powdery, granulated, fibrous and coarse materials with high contamination by iron. An example is separation of magnetic and non-magnetic blasting agents. The separators are capable of removing even very small or weakly magnetic particles when at low feed capacities with a vibrating feeder. Drum separators have a low installation height, are continuously cleaned and achieve high magnetic field strength.

These devices can be used for both dry and wet magnetic separation processes.

Need help? Write us

Want to know more? Take a look into our international technical database to see detailed product specifications.

You will be redirected to the joint technical database of the Goudsmit Magnetics group for a detailed description of the product.

I agree to redirecting Cancel redirecting