Steel Shafts Demagnetization

Demagnetisation of steel shafts to protect of metal dirt sticking.

A customer asked us to help remove residual magnetism on 17 steel shafts.

Residual magnetism is a major problem for maintaining production quality. Metal dirt, dust and dirt gets caught and held especially on the edges where there is a large magnetic field gradient. You can imagine what such impurities can do when assembling precision molded components. It's a significant complication that we can solve. Magnetization of shafts and semi-finished products is virtually unavoidable. Magnets are used from quality control to handling. So don't forget the possibility of prescription demagnetization in production technologies.

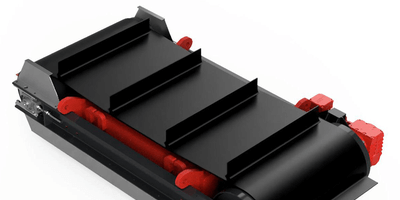

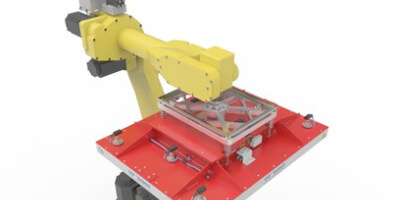

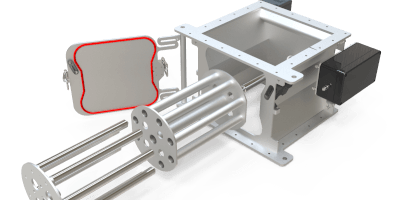

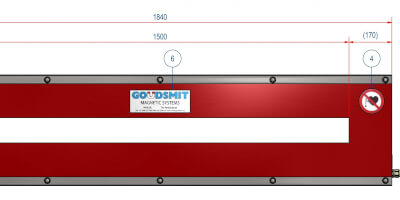

In this particular case, we carried out demagnetisation at the customer's manufacturing plant. Shafts with a diameter of 150 - 180 mm and a length of 1000 - 1500 mm were demagnetized by passing them vertically through a demagnetization tunnel. Handling was carried out using suspended fabric straps to minimise the impact on the handling equipment. Demagnetization at the customer's site we offer as a service.

The value of the original magnetism was 180 to 210 Gauss, the magnetism after demagnetization dropped to the required value of 3 to 10 Gauss.

We helped to solve the problem with impurities. The customer expressed interest in purchasing a demagnetization tunnel so that they could perform the demagnetization themselves as part of the manufacturing process. It's really easy! You can find detailed information about the demagnetization systems here.

If you have a similar problem, please contact us. We will be happy to help you with a solution.