Demagnetisation of Turbine Rotor

Removal of undesirable magnetism before welding.

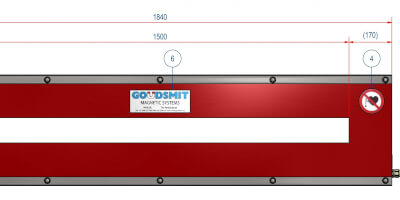

A customer contacted us with a request for removing residual magnetism from a semi-finished rotor shaft of a gas turbine. The rotor shaft is welded together from parts and inspection of the semi-finished product revealed the presence of a residual magnetic field. Its values were between 40 – 70 Gauss. A magnetic field of such intensity affects the welding arc and endangers the quality of the weld joint. The quality of weld joints is vital for components that undergo high stress and a gas turbine rotor certainly fits those criteria. It was, therefore, necessary to perform demagnetisation.

Due to the size of the rotor (ca 1.5 m x 8 m), demagnetisation was performed on-site of the rotor's production. Our technicians demagnetised the component using a special mobile demagnetisation unit. The device enables performing both standard demagnetising of smaller and thinner steel components as well as special demagnetisation of large forgings or weldments. Thanks to the wide range of settings available on the device and to the experience of our workers, we can assist our customers in resolving problems with undesirable magnetic fields even in large or unusual forged pieces.

Our technicians carried out the demagnetisation procedure and the residual magnetism value was reduced from 40 – 70 Gauss to under 15 Gauss, which was an acceptable value for the customer and would not cause further issues during rotor production. Do you have a similar issue?